Lasers, welding, technology, cool, fun stuff! This unique technology allows to approximate different materials with extreme strength and precision. Using lasers for welding, we can ensure that the pieces fit in perfectly. It is extremely useful for jobs that require quick and accurate welding such as in automobiles and buildings. Laser welding can forge these strong bonds because it is precise and can also keep the materials together for a considerable time.

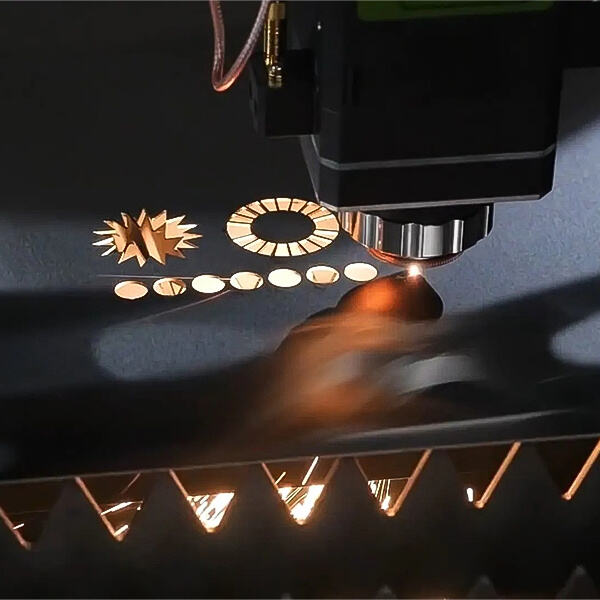

Another fabulous technology is laser cutting. This technology aids many businesses by shaping and sizing rough materials. Think of a large metal chunk that works as a component for a toy. Laser cutting ensures it’s cut into the right shape … just right. This is particularly significant as it enables factories to produce visually appealing and consistent products which helps in cross-comparison. When everything is manufactured the same, it helps keep the consumer pleased with what they purchase. That’s especially helpful when they have to slice materials very quickly and finely.

Laser welding and cutting machines are incredibly efficient and precise. This speed is extremely vital for producing products in factories. If a machine can cut or weld in a timely and accurate manner, it saves the company time and money. With powerful software capabilities, and the ability to cut and carve into materials, these machines can get the job done. They can, for instance, carve beautiful patterns into metal or weld heavy parts together.

The utilization of expert laser machines is becoming common worldwide among factories. We are the ZPLASER — machines you can trust to do it right, every time. These machines are powerful and able to take anything you throw at them, welding or cutting tasks. Planned obsolescence effects tive, so businesses are better aware of making a wise decision to purchase them.

What is there to make with laser welding and cutting? You can design pretty much any shape or design you'd like! This is good for artists and designers, and for factories that make products. An artist could use these machines to design one-of-a-kind sculptures, while a factory could use them to produce pieces for factory-made toys or cars. The creativity is endless and the results can be truly terrific!

ZPLASER is recognized for producing high-quality fast and high-performance machines. They’re built to last, which means businesses can depend on them for years to come. These machines provide the best results in all the time, which helps enterprises to work in a much smoother way. ZPLASER's machines are revolutionizing manufacturing with their specialized technology

Service customers that is effective. With quick response times well as reliable laser welding and cutting machine support solutions, ensure quick after-sales assistance available.Comprehensive customer files. In addition, follow up promptly on customer needs and feedback, establish a long-term friendly partnership with each our customers.

More competitive. Based the requirements of customers and market demand company will focus mastering the basic technology independent R D and production lines which will improve performance of equipment, while reducing laser welding and cutting machine costs and increasing market competitiveness.

Reliable quality. With high laser welding and cutting machine, high durability stability, meet customers' high requirements.Control quality assurance. Professionally managed procurement, production after-sales service are essential a comprehensive set quality programs.

Research development. With the most advanced technical capabilities an impressive R D capability to meet a variety of needs.Equipment's talent. We always put laser welding and cutting machine on development industrial processes and technological advancement through the contribution of highly qualified engineers and professional researchers.